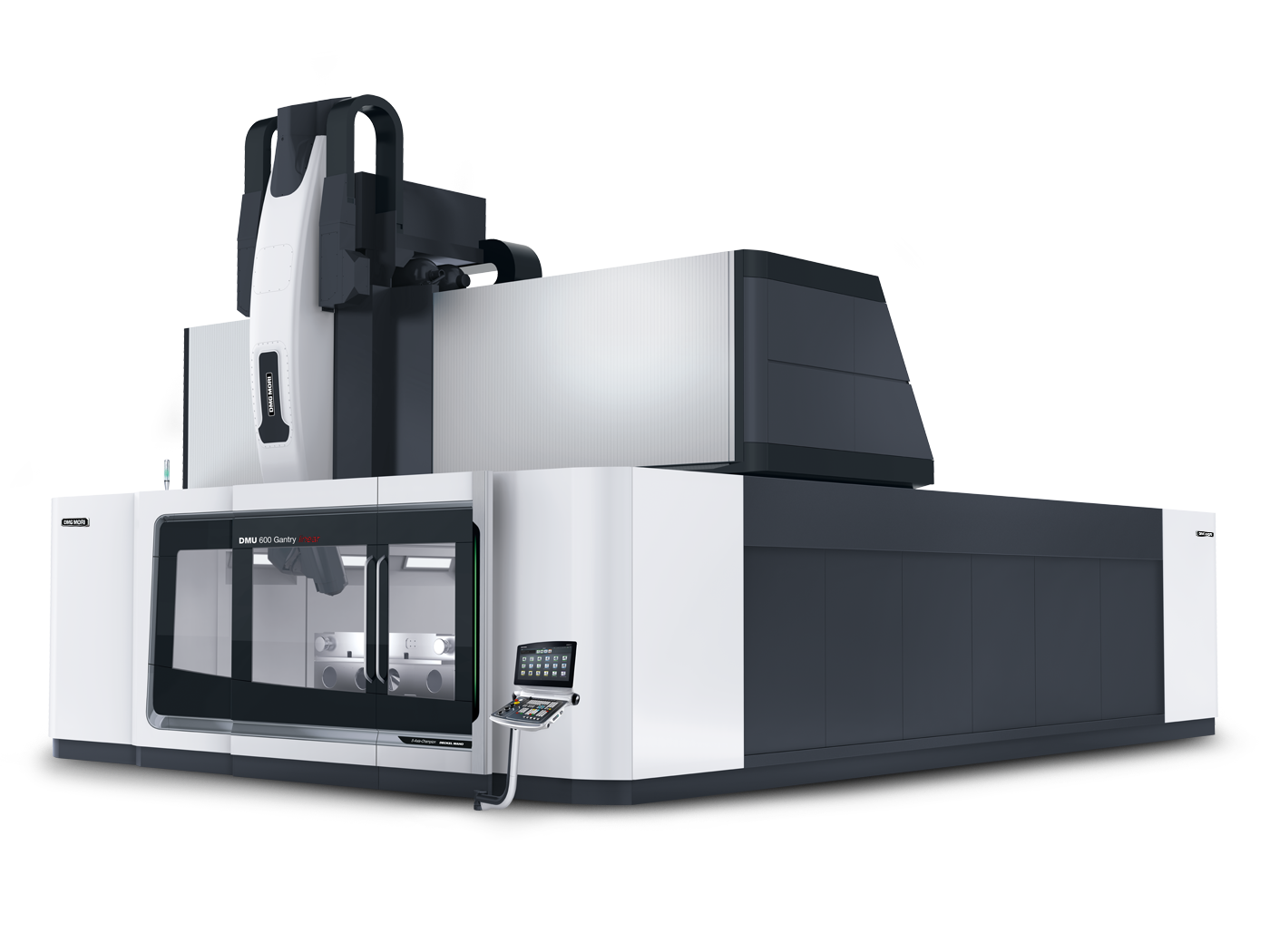

DMG Mori’s DMU 340 Gantry machining centre has universal appeal. DMG Mori has released its DMU 340 Gantry machining centre. The machine has a one-piece, thermo-symmetrical EN-GJS-600 cast iron machine bed accommodating a working volume of 3,400 by 2,800 by 1,250mm, which is expandable to 6,000 mm in the X-axis and 1,500 mm in Z.

Precision

- Maximum accuracy through water-cooled feed drives

- Band filter unit with 2,500 l as standard

- Highest long-term accuracy due to cooled linear guideways and active spindle growth control.

Performance

- High dynamics with feed speed up to 40,000 mm/min

- High feed power up to 50 kN

- Biggest spindle range in the market: powerMASTER motor spindle with up to 1,000 Nm and torqueMASTER gear spindle with 1,800 Nm

Efficiency

- Lower energy consumption through intelligent needs-based power units.

- Gantry design with vertically moving cross beam with hydraulic weight compensation.

- Fast innovative wheel type magazine with up to 243 tools with minimized footprint.

Flexibility through spindle versions

- Vertical spindle with 20,000 rpm

- 45° head and 90° head for 5-axes machining up to 30,000 rpm

- Ready for new technologies like Ultrasonic, Laser or machining of carbon material

Working area concept

Dmg Mori Dmu 340 Gantry Seating

- Fixed table 2,250 x 2,000 mm with 10,000 kg loading capacity

- T-slots across the table for easy chip removal

- Chip conveyors on both sides of the table

Low Gantry Design

Dmg Mori Dmu 340 Gantry 2017

- 50 m/min rapid traverse

- Best visibility into the working area through missing side walls

- Maximum utilisation of the working area